Every time you effortlessly travel from one point to another, you’re not just relishing the convenience of your vehicle but also appreciating the intricate engineering that ensures its safety and dependability. Beyond the comfort and protective elements lies a lesser-known yet vital aspect: the meticulously optimized mechanical performance of microstructured materials. These materials, though often overlooked, play a pivotal role in strengthening your vehicle, guaranteeing resilience and robustness throughout every voyage.

Fortunately, scientists at the MIT Computer Science and Artificial Intelligence Laboratory (CSAIL) have delved into this realm. A team of researchers has transcended conventional trial-and-error approaches to develop materials with exceptional performance through computational design. Their innovative system amalgamates physical experiments, physics-based simulations, and neural networks to navigate the disparities commonly encountered between theoretical models and practical outcomes. One of the remarkable breakthroughs includes the unveiling of microstructured composites—utilized in various applications from automobiles to aircraft—that exhibit heightened toughness and durability, striking an optimal equilibrium between stiffness and toughness.

Beichen Li, an MIT PhD student in electrical engineering and computer science, CSAIL affiliate, and the lead researcher on the project, expressed, “Composite design and fabrication are fundamental to engineering. The implications of our work extend beyond solid mechanics. Our methodology serves as a blueprint for computational design adaptable to diverse fields such as polymer chemistry, fluid dynamics, meteorology, and even robotics.”

The findings of their work were recently published in an open-access paper in Science Advances.

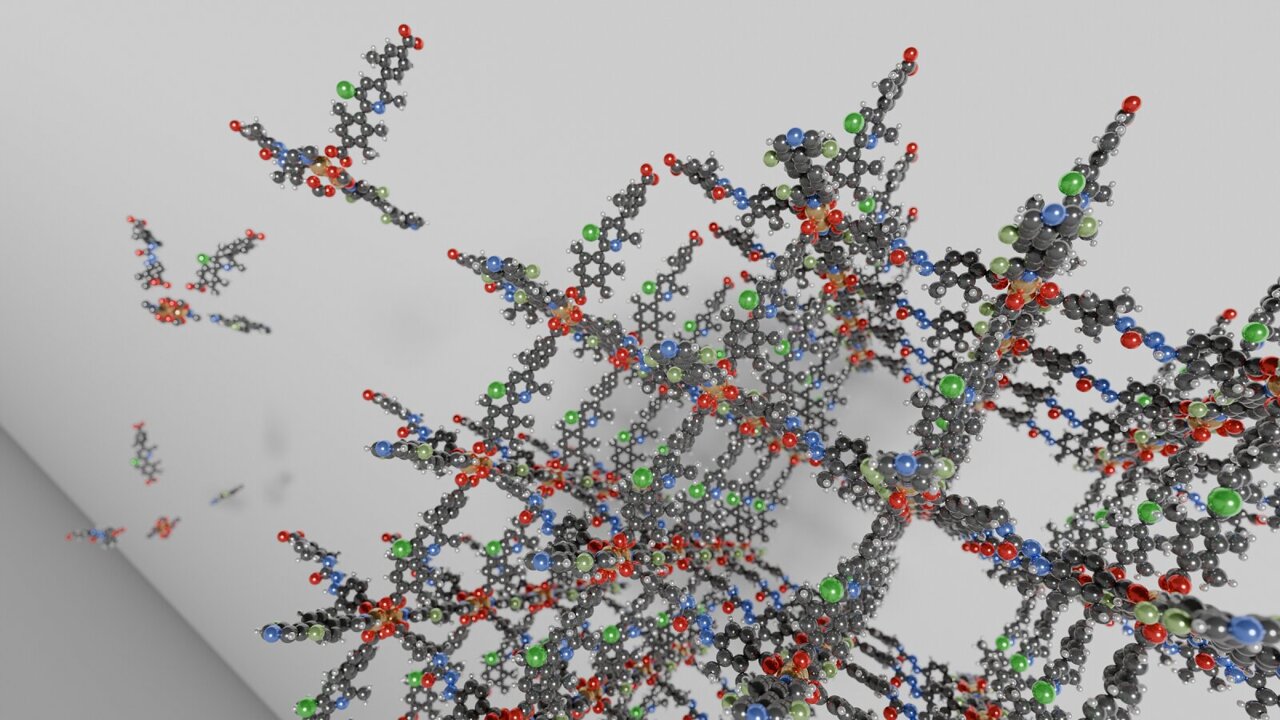

In the dynamic realm of materials science, atoms and molecules act as miniature architects, perpetually collaborating to shape the future. Each element must find its ideal counterpart, and in this context, the emphasis was on striking a balance between two crucial material properties: stiffness and toughness. Their methodology involved exploring a vast design space comprising two types of base materials—one rigid and brittle, the other soft and malleable—to uncover optimal microstructures through various spatial arrangements.

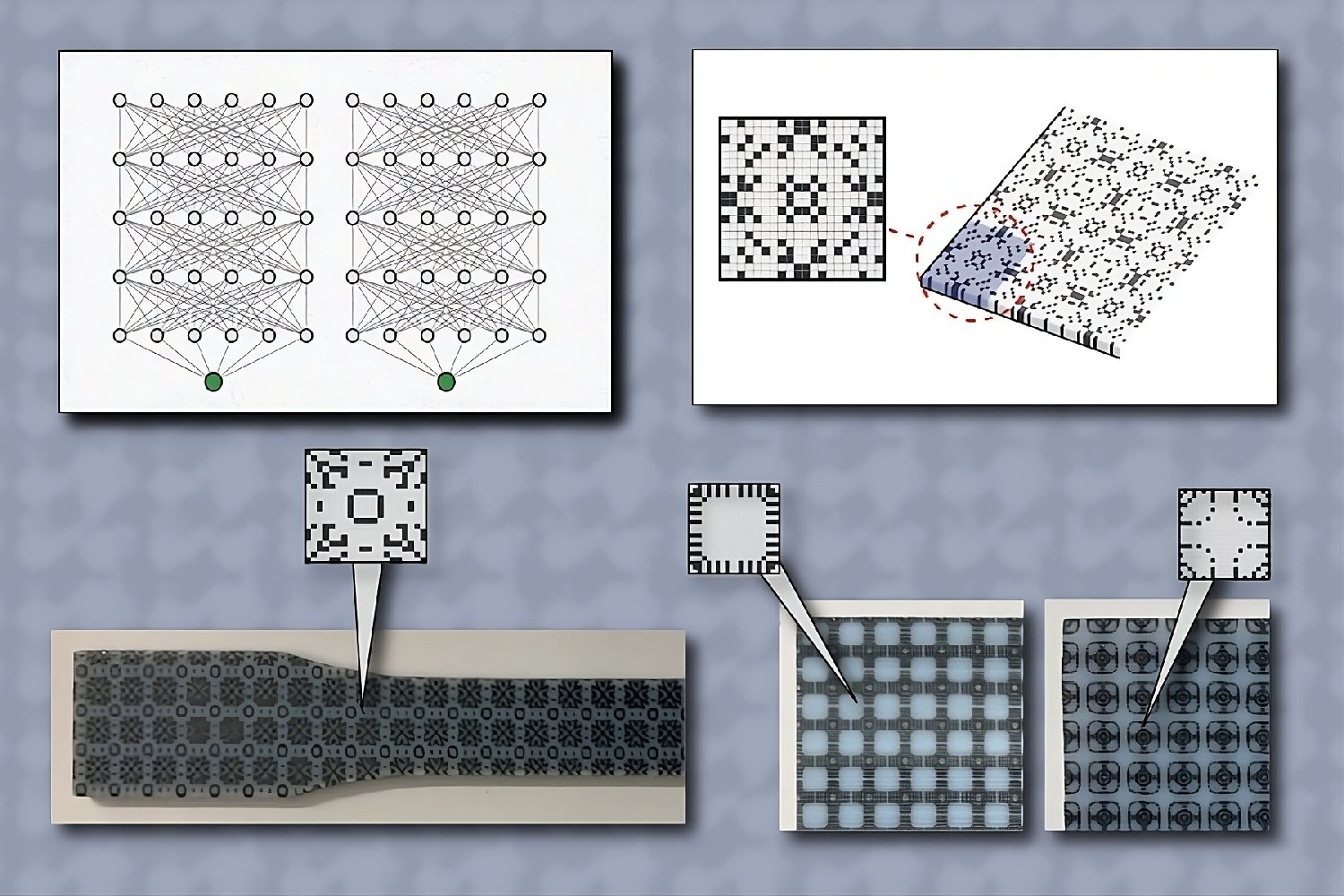

A pivotal innovation in their approach was the integration of neural networks as surrogate models for simulations, streamlining the material design process. Li elaborated, “This evolutionary algorithm, accelerated by neural networks, guides our exploration, enabling us to efficiently identify the best-performing samples.”

Enchanting Microstructures

The research team initiated the process by fabricating 3D printed photopolymers, approximately the size of a smartphone but slimmer, incorporating a small notch and a triangular cut in each specimen. Following a specialized ultraviolet light treatment, the samples underwent evaluation using a standard testing machine—the Instron 5984—for tensile testing to assess strength and flexibility.

Concurrently, the study seamlessly integrated physical experiments with advanced simulations. Leveraging a high-performance computing framework, the team could anticipate and refine material characteristics prior to physical realization. A notable achievement lay in the intricate technique of bonding diverse materials at a microscopic scale—a process involving a complex pattern of minute droplets that fused rigid and pliable substances, achieving the delicate balance between strength and flexibility. The simulations closely mirrored the outcomes of physical tests, validating the overall efficacy of the approach.

Complementing the system was their “Neural-Network Accelerated Multi-Objective Optimization” (NMO) algorithm, designed to navigate the intricate design landscape of microstructures, unveiling configurations showcasing nearly optimal mechanical attributes. The workflow functions akin to a self-correcting mechanism, continuously honing predictions to align closely with reality.

Nevertheless, the journey was not devoid of challenges. Li underscored the hurdles in maintaining consistency in 3D printing and integrating neural network predictions, simulations, and real-world experiments into an efficient pipeline.

Looking ahead, the team is dedicated to enhancing the usability and scalability of the process. Li envisions a future where laboratories are entirely automated, minimizing human intervention and maximizing efficiency. “Our objective is to automate everything, from fabrication to testing and computation, within an integrated lab setup,” Li concluded.

Collaborating with Li on the paper are senior author and MIT Professor Wojciech Matusik, along with Associate Professor Tae-Hyun Oh from Pohang University of Science and Technology, and MIT CSAIL affiliates including Bolei Deng, now an assistant professor at Georgia Tech; Wan Shou, currently an assistant professor at the University of Arkansas; Yuanming Hu MS ’18 PhD ’21; Yiyue Luo MS ’20; and Liang Shi, an MIT graduate student in electrical engineering and computer science. The research endeavors of the group received partial support from Baden Aniline and Soda Factory (BASF).