Once the method gains broader acceptance, researchers suggest that it could pave the way for the development of additional treatments for heart conditions and cancer.

In Austin, Texas, the pervasive presence of artificial intelligence is unmistakable, permeating various aspects of our lives from online shopping to music composition and even communication.

At the University of Texas, a team of researchers is harnessing the power of AI to expedite the manufacturing process of medications used in Alzheimer’s treatment.

Daniel Diaz, a postgraduate Ph.D. student at UT and the head of the Deep Proteins group at the Institute for Foundations of Machine Learning, expressed optimism about the impact of AI on their endeavors. Diaz emphasized the role of AI in accelerating their progress and overcoming obstacles in their research.

The team’s current focus lies in leveraging AI for bioorganic chemistry applications, particularly in relation to a key component derived from the wild daffodil, which is instrumental in producing the Alzheimer’s drug galantamine.

Diaz highlighted the vulnerability of their supply chain, as the primary source of the crucial ingredient is the wild daffodil predominantly found in Scotland. Any disruption in the daffodil supply, such as a famine or disease outbreak, could have significant ramifications for medication production.

To illustrate the resource-intensive nature of the process, Diaz noted that producing a pound of the medication necessitates the use of 333 daffodils, with the active ingredient costing \(23,000 per pound and the prescription priced at \)80.

The team’s objective is to synthesize the genetic material of the daffodil to replicate the proteins responsible for drug synthesis, a task made feasible with the assistance of AI technology.

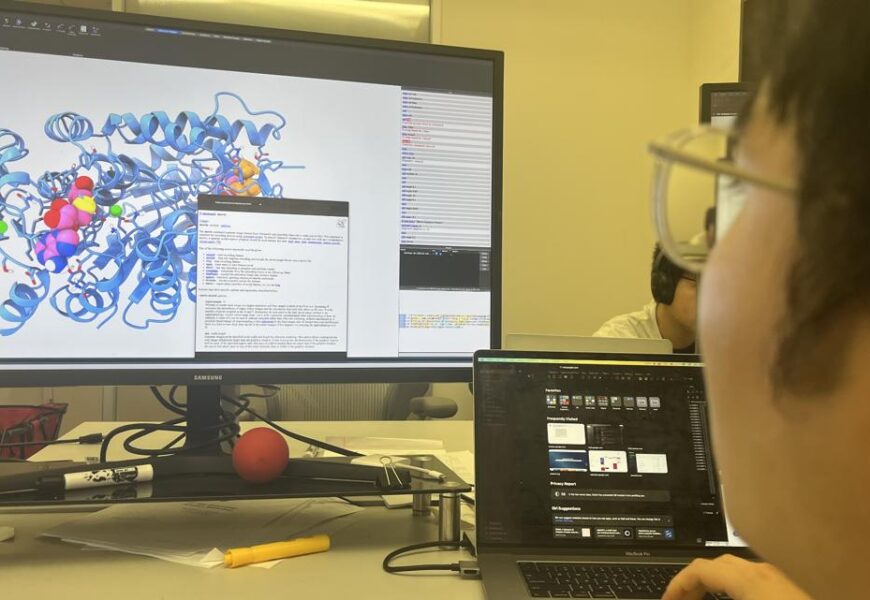

By employing the AlphaFold AI software and bio-sensor technology developed by Simon d’Oelsnitz, the researchers have significantly enhanced their efficiency in identifying optimal proteins and evaluating their efficacy.

Diaz underscored the transformative potential of AI in expediting the discovery and optimization of proteins, a process that traditionally spans months to years but has been expedited to three to five months with AI assistance.

Despite the advancements facilitated by AI, Diaz acknowledged the indispensable role of human expertise, as evidenced by the collaboration with structural biologist graduate student Wan Tae Kim to address discrepancies in the protein structure.

Looking ahead, Diaz envisions a future where AI not only streamlines the manufacturing process but also eliminates the reliance on natural sources like daffodils, thereby reducing costs and increasing accessibility to medications.

As the technology evolves rapidly, Diaz anticipates broader applications beyond Alzheimer’s medication, foreseeing the bio-manufacture of diverse medications, including synthetic alternatives for heart disease, cancer, and other ailments.

The team is actively engaged in unraveling the remaining genetic material required for drug synthesis, marking a significant step towards advancing pharmaceutical production through AI-driven innovations.