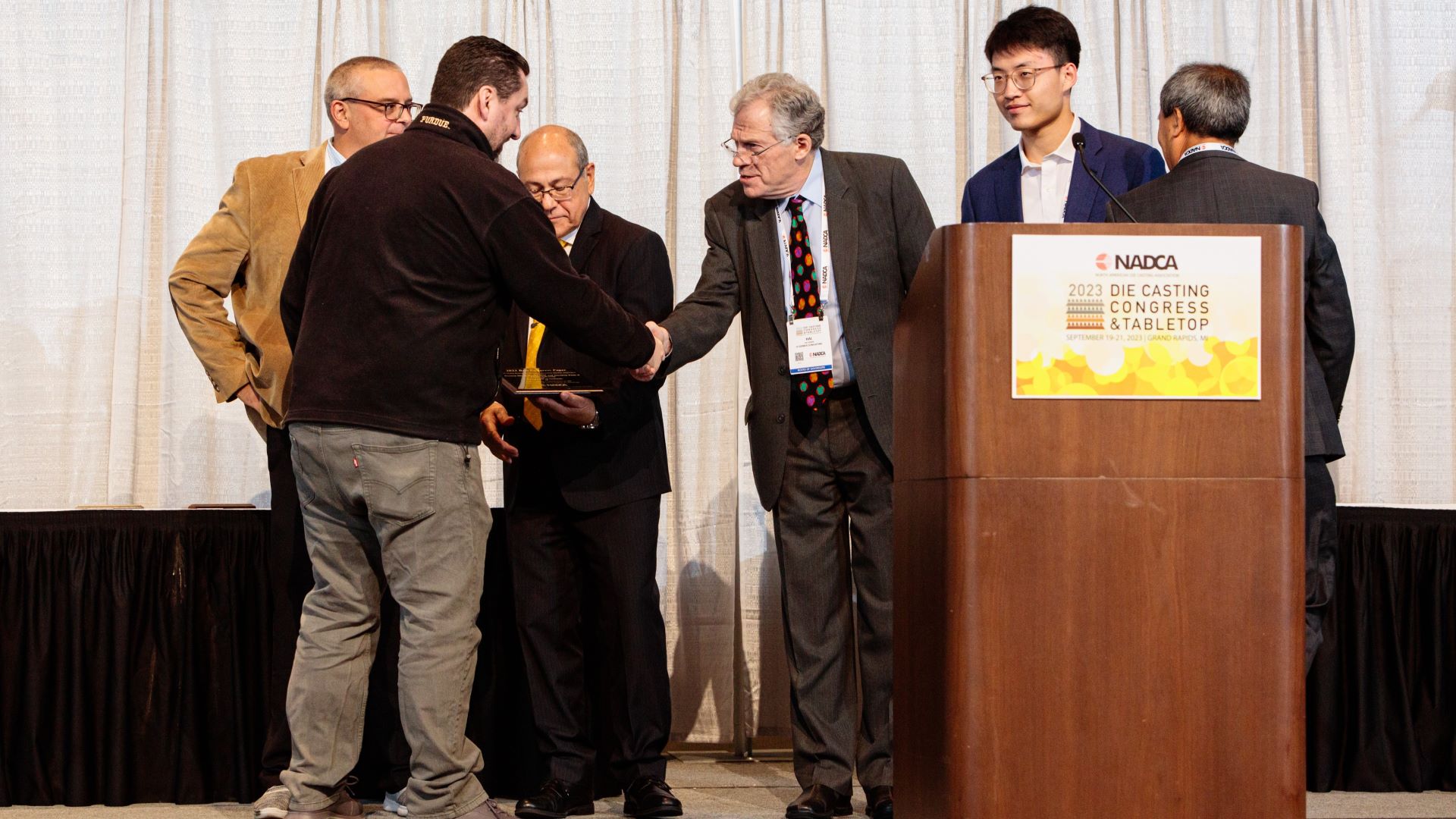

The annual conference in Grand Rapids, Michigan, hosted by the North American Die Casting Association (NADCA), recognized four authors with the prestigious “Best Congress Paper” award.

Boxiang Zhang, Xiaoming Wang, Baijian “Justin” Yang, and Corey Vian, all affiliated with Purdue Polytechnic, played key roles in this accolade. Zhang, a Ph.D. candidate, collaborated with Wang, an associate professor of engineering technology, while Yang, recently appointed as an associate professor for research at Purdue Polytechnic, joined forces with them in their research endeavors.

The quartet was complemented by Corey Vian, a manufacturing executive manager at Stellantis’ Kokomo facility, bringing valuable industry expertise to the team. Vian, an alumnus of Purdue Polytechnic, also serves as a sponsor for thesis projects in engineering technology at the undergraduate level.

Operational Overview

Their collective effort culminated in a presentation on “A. I Vision System for Automated Casting Quality Inspection.” Focused on metal die-casting, a process involving high-pressure injection of molten metal into molds, the team highlighted the significance of quality control in this manufacturing domain. The applications of such precision span diverse industries, from electronics to household appliances.

Presently, ensuring quality control in casting processes poses significant challenges, often necessitating manual inspections. The authors’ research underscored the inefficiencies associated with manual assessments, leading to a high volume of wastage and defective outputs reaching consumers.

In response to these challenges, the team proposed an innovative solution leveraging an AI-based vision system. This cutting-edge “Vision Transformer” not only identifies anomalies swiftly but also precisely pinpoints their locations, facilitating a more streamlined production process. By harnessing deep neural network technologies, the system promises cost savings by reducing the incidence of scrapped components.

Broadening the Research Horizon

The collaborative efforts of Zhang, Wang, and Vian date back to the Tech Expo for the year 2023, organized by Purdue Polytechnic’s School of Engineering Technology. This early engagement laid the foundation for their subsequent involvement in this groundbreaking study.

Vian’s prior collaboration with engineering technology students from Purdue Polytechnic tasked them with developing a defect-detection system. These students, under Vian’s mentorship, designed the mechanical and electrical components integral to the AI vision system. This initiative, guided by Wang’s leadership, culminated in a partnership with Zhang to refine the AI’s fault-detection algorithms.

The award-winning paper, recognized by NADCA, not only encapsulates the team’s research findings from the previous quarter but also outlines strategies to further enhance the AI vision system based on these insights.